Quick links:

Assessing risks

Manual handling safety techniques

4 Steps to safe manual handling

What is manual handling?

Manual handling is defined by the Manual Handling Operations Regulations 1992 (MHOR) as “any transporting or supporting of a load (including the lifting, putting down, pushing, pulling, carrying or moving thereof) by hand or bodily force”.

Consider how many of your daily tasks, or those carried out in your workplace, could fall into this definition:

- Carrying a tray of food or drink

- Mopping the floor

- Carrying a pile of books or resources

- Wallpapering

- Building or moving furniture

Often, the impact of these tasks on our bodies is only noticed over longer periods of time where the task has been repeated. For this reason, these tasks can be overlooked, resulting in a lack of appropriate training or support.

In 2020/21, 470,000 workers suffered from work-related musculoskeletal disorders. 45% of these were injuries to the upper limbs or neck, with 39% being injuries to the back. The construction and human health and social work industries had higher than average rates of musculoskeletal disorders.

Employer responsibility for manual handling tasks

The Manual Handling Operations Regulations require employers to avoid the need for hazardous manual handling as far as possible, assess the risks for unavoidable tasks and reduce the risks for these tasks.

It is crucial that businesses carefully assess the risks of manual handling in order to provide suitable support for their employees and avoid injury. Use our specific Manual Handling Risk Assessment booklet and folder to ensure you have considered all risks and have a record of health and safety adaptations you have made.

Assessing the risks of manual handling

There are four key areas to consider if you are evaluating the impact of manual handling tasks. When thinking about manual handling, remember to think LITE: Load, Individual, Task and Environment.

Load – how might the object being moved impact the challenge?

- Shape – is it easily moved or does the shape make it awkward?

- Weight – is it an appropriate weight for the chosen method of movement?

- Stability – could the load shift during movement?

- Handholds – is it specifically designed for carrying?

- Contents – are the contents hazardous in any way?

Individual – how might the worker impact the challenge?

- Capability – has the worker been trained and do they have the physical capabilities to carry out the task? Is it an unusual movement that will require experience and training?

- PPE – could protective equipment impede the task in any way, for example reducing visibility or dexterity?

- Circumstances – does the worker have any specific circumstances that need to be considered, e.g. pregnancy?

Task – how might the action and method impact the challenge?

- Ease – is it manageable?

- Alternatives – is this the only/best way to move the load?

- Adaptations – can changes be made to make the movement safer or easier?

- Position – how close to the body can the load be held?

- Aids – can mechanical aids such as hoists or trolleys be used?

Environment – how might the space impact the challenge?

- Space – does the space make the movement more difficult?

- Temperature – could cold impact sensation and the worker’s grip, or could heat increase the likelihood of sweat and a reduced grip?

- Flooring – could varying floor levels, or slippery surfaces pose a danger?

- Lighting – can the worker easily see the area?

- Changeability – is the environment likely to change suddenly, for example if you are outdoors?

Manual Handling Safety Techniques

Provide suitable manual handling guidance and consider sending employees on a manual handling training course.

Be prepared for possible injuries by ensuring your first aid equipment is appropriate for your work environment and fully stocked. For example, consider the need for additional hot/cold packs used with sleeves or compression cuffs, which can help with swelling and pain relief, as can muscle rub.

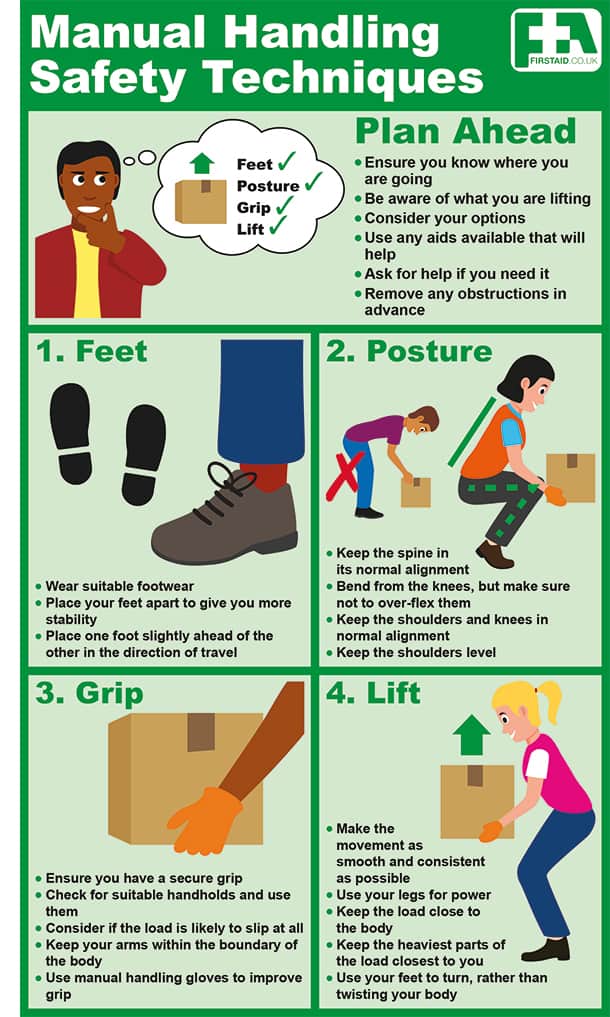

Before you start any manual handling, plan ahead and assess the situation:

- Ensure you know where you are going

- Be aware of what you are lifting

- Consider your options

- Use any aids available that will help

- Ask for help if you need it

- Remove any obstructions in advance

Then follow the simple steps below to keep yourself safe.

Four steps to safe manual handling

View the printable "Safe Steps to Manual Handling" PDF.

-

Think about your feet:

-

Wear suitable footwear

- Place your feet apart to give you more stability

- Place one foot slightly ahead of the other in the direction of travel

-

-

Think about your posture:

-

Keep the spine in its normal alignment

- Bend from the knees, but make sure not to over-flex them

- Keep the shoulders and knees in normal alignment

- Keep the shoulders level

-

-

Think about your grip:

-

Ensure you have a secure grip

- Check for suitable handholds and use them

- Consider if the load is likely to slip at all

- Keep your arms within the boundary of the body

- Use manual handling gloves to improve grip

-

-

Lift carefully:

-

Make the movement as smooth and consistent as possible

- Use your legs for power

- Keep the load close to the body

- Keep the heaviest parts of the load closest to you

- Use your feet to turn, rather than twisting your body

-

Read our blog for more information on first aid, or contact us for further advice and information on our products.