The EN388 Test

The European EN 388 Standard was designed to assess the performance of a fabric or layers of fabric to determine their ability to withstand puncture, cuts, tears and abrasions. The procedure includes a separate test for each of these qualities and a performance level is awarded according to each result.The CE Certification (European Mechanical Test EN388) provides puncture resistant performance levels based on tests with a probe that simulates larger threats (think nails or barbed wire) but is ineffective at determining resistance to small high-risk threats like slivers of glass, metal shards or needles. Hypodermic needles, while an important consideration for many jobs, are difficult to test because they easily bend.

TurtleSkin's Puncture Test

TurtleSkin has developed its own puncture test that uses a 1.27mm solid steel needle in a controlled laboratory environment – their test needle is 3.5 times sharper than the one used in the standard EU EN388 test. Like the EN388 test, however, their probe doesn’t simulate threats such as hypodermic needles, glass slivers and metal shards.

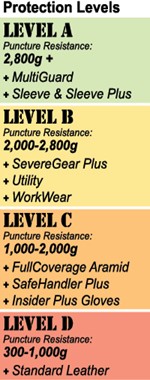

TurtleSkin has developed its own puncture test that uses a 1.27mm solid steel needle in a controlled laboratory environment – their test needle is 3.5 times sharper than the one used in the standard EU EN388 test. Like the EN388 test, however, their probe doesn’t simulate threats such as hypodermic needles, glass slivers and metal shards.Based on their own more rigorous test, each TurtleSkin Safety Glove is classed into a level of puncture resistance. The results show that TurtleSkin gloves are between 91% – 264% more puncture resistant than standard leather gloves. For a glove thinner than three sheets of paper, TurtleSkins are the market leaders in precise and dextrous puncture resistance.

TurtleSkin EN388 Test Results

Puncture resistance & dexterity

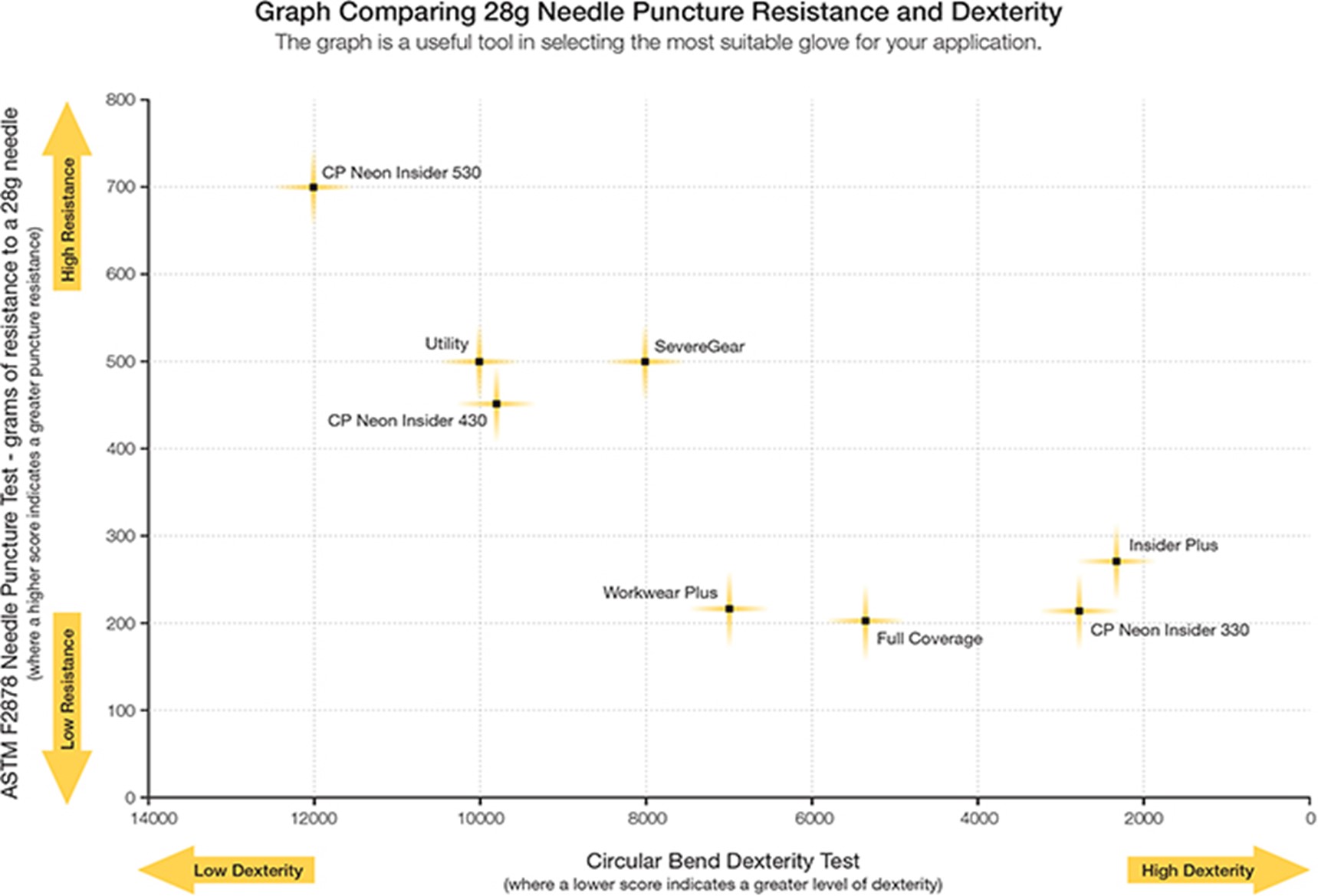

TurtleSkin gloves are designed and tested to specifically resist fine sharps and maintain dexterity. As the EN388 puncture test does not measure effectiveness against small sharps like needles or splinters, they also test TurtleSkin gloves with the ASTM F2878 test – a US standard that uses either a 21G, 25G or 28G needle as its probe.For their testing, they fire a 28G needle at the glove at a speed of 500mm per minute. They repeat this 12 times, and the average force required to puncture the material is recorded. They then test the dexterity of their gloves by measuring the amount of force required to push the gloves through a circular ring. The greater the force required, the higher the score and the lower the level of dexterity the glove they offer.

Read our other blogs for more information on first aid or contact us for further advice and information on our products.

About the author:

Jo Stokes is a writer, marketer and trained first aider at First Aid Online.

Find out more about Jo.

By Jo Stokes

Explore more: Workplace first aid & safety