What is eye wash used for?

Our eyes are delicate and vulnerable, and the consequences of damage to them can be devastating. The first step is to make sure all measures are taken to protect the eyes in the first place – generally safety goggles or glasses should be used for any activity or job that has the potential to damage the eyes.

Any activity that could cause particles (from dust and dirt to wood and metal) to fly in the air poses a risk to the eyes. This could include workplace activities, such as construction or mining, but could also include household activities, such as mowing the lawn and DIY. In schools, staff and students may need protection during science or 'design and technology' lessons.

Eye wash is a necessary first aid supply for those times when something does manage to get into a person’s eye, despite all safety precautions. Some workplaces may have special eye showers installed, or it may be possible to use an ordinary tap to irrigate the eye. However, there are many situations where running water may not be available or accessible enough for someone to use on their eye. In these circumstances, eye wash or eye baths can provide quick and effective pain relief, as well as reducing the likelihood of further serious damage to the eye.

Eye wash is a necessary first aid supply for those times when something does manage to get into a person’s eye, despite all safety precautions. Some workplaces may have special eye showers installed, or it may be possible to use an ordinary tap to irrigate the eye. However, there are many situations where running water may not be available or accessible enough for someone to use on their eye. In these circumstances, eye wash or eye baths can provide quick and effective pain relief, as well as reducing the likelihood of further serious damage to the eye.

Similarly, there are times when eye protection is not practical or realistic, despite the possible risks. Children playing on a sandy beach, for example, are at quite a high risk of getting sand in their eyes, but certainly wouldn’t be expected to wear safety goggles! In these situations, having eye wash or an eye bath handy – in the family first aid kit, the car first aid kit, or as part of a beach lifeguard station – can help to save a lot of tears and pain:

What can I use to wash my eyes?

Before washing your eyes for any reason, be sure to remove contact lenses first.

If the eye has been contaminated with particles, then water or eye wash can be used to flush out the eye until the object is removed.

If the eye has been contaminated with chemicals, you should read the chemical packaging for instructions, but the eye will most likely need to be rinsed continuously for at least 15 minutes. Eye wash can either be used as an interim measure, whilst the casualty is moved to somewhere with clean running water, or it may be used continuously for the entire duration – though this would require large reserves of bottled eye wash.

Is eye wash just water?

To ensure its sterility, HypaClens eye wash is a saline solution containing 0.9% Sodium Chloride. It works simply by diluting and flushing away any contaminants and is a substitute for using tap water.

However, for chemical contamination of the eye, a more effective alternative is available. Cederroth’s eye wash is a buffered solution. It restores the eye’s pH to normal levels more quickly than tap water or standard eye wash, helping to minimise the harm and reduce the likelihood of permanent sight loss. Cederroth eye wash is effective against acidic and alkaline substances but is particularly effective at neutralising alkalis which are also more damaging to the eye.

Where should an eye wash station be located?

Eye wash in the home

In the home, the location of eye wash will depend on where it will most likely be needed. If a lot of DIY happens in the garden shed, for example, that would be a great place to keep the eye wash, ideally with a mirror nearby. Otherwise, the kitchen or a bathroom cabinet would be the best place to store it – somewhere that can be easily and quickly accessed in an emergency.

Eye wash in the workplace

Workplaces are required to consider eye care and eye wash needs as part of their risk assessments. The more obvious examples of workplaces requiring eye wash are those working with harmful chemicals, industrial cutting equipment or grinding wheels. However, there are less obvious workplaces that sometimes get overlooked. Warehouses, for example, may have a lot of packaging dust in the air; agricultural work can also be very dusty or involve flying particles of grass or crops, which can irritate the eyes.Where the need for eye wash facilities (such as an eye wash station, or eye wash bottles) has been identified in the workplace risk assessment, the HSE regulations state that at least one litre of sterile water or sterile saline should be provided in sealed, disposable containers. Once the seal is broken, the containers cannot be kept for reuse. This means that workplaces requiring eye wash should have a minimum of two litres in separate containers, allowing for supplies to still be immediately available if one of these is used.

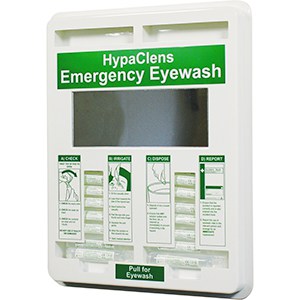

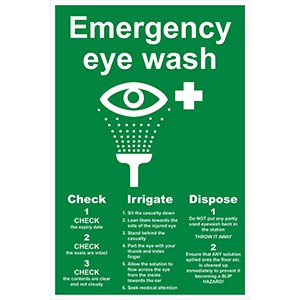

Eye wash facilities should be located near the major hazards to eye health. It should be fixed to the wall, easy to access and on the same level as the hazard, not requiring stairs or a ladder to reach. It should be clearly sign-posted and a mirror may be helpful to allow casualties to treat themselves.

In addition to eye wash, two sterile eye pads are suggested as a minimum first aid supply in any workplace. These are included in any British Standard first aid kit but are also included in many eye wash station products.

View all our Eye Wash Kits, Stations, Points & Dispensers

A final consideration for workplaces is visibility. Ensuring all employees know where to find first aid when necessary is a requirement of health and safety provision in the workplace. Signs to remind employees of protecting their eyes, as well as the location of first aid and how to provide it are useful reminders.

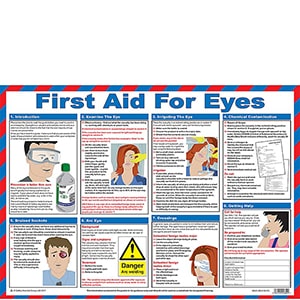

First aid for eye contamination

How to treat eyes contaminated with dust, dirt or other particles

- Ask the casualty what they have been doing and if they know what has caused their eye irritation/injury

- Ask the casualty to remove contact lenses, if worn

- Get the casualty to sit down, leaning slightly back and inclined towards the side of the contaminated eye

- Standing behind them, use your thumb and index finder to gently separate the eye lids

- Ask the casualty to look up, down, left and right so you can look for any foreign bodies on the eye’s surface

- Begin irrigation (eye wash or eye bath – see instructions below). If you are using sterile eye wash, check the following first:

- The bottle is sealed

- The product is within the expiry date

- The contents of the bottle are not cloudy

How to treat eyes contaminated with chemicals

- Check for further danger to you or to other parts of the casualty’s body – if available, wear gloves

- Ensure contact lenses have been removed, if worn

- Quickly place the casualty in a reclined sitting position

- Immediately start to irrigate the eye (see below), making sure that the water runs away from the casualty’s face

- Ask another colleague to identify the chemical that has contaminated the eye, and to check the label for further advice. They should also check the organisation’s COSHH data sheet

- After eye irrigation, cover the eye and seek medical aid

- Do not do any of the following:

- Send the casualty back to work without getting a medical opinion

- Throw away any chemical containers – these may be useful for information

- Attempt to neutralise the chemical with other chemicals

How to use eye wash

- Remove contact lenses, if worn

- Tilt the head back and pour eye wash over the eye, ensuring the water runs away from the unaffected eye. Some eye washes have special fittings on the end to fit securely around the eye.

- If the eye is contaminated with dust or dirt, continue to do this until the contamination is removed

- If the eye is contaminated with chemicals, wash out for at least 15-20 minutes or as per the chemical data sheet instructions

- Cover the eye with an eye pad. The unaffected eye may also need to be covered to prevent eye movement

- Seek medical advice to ensure there has been no damage to the eye.

How to use an eye bath

- An eye bath can be useful to avoid wasting eye wash or if you are administering eye wash to yourself.

- Rinse out the eye bath before use

- Remove contact lenses, if worn

- Pour eye wash into the eye bath – between a third and half full

- Bend your head forwards to place your eye over the eye bath, fitting it carefully around your eye socket

- Tilt your head up again, holding the eye bath against the eye socket, until the eye wash flows over your eye

- Keep the eye open and rock your head from side to side for around 30 seconds

- Cover the eye with an eye pad. The unaffected eye may also need to be covered to prevent eye movement

- Seek medical advice to ensure there has been no damage to the eye.

Eyes embedded with foreign bodies

If a foreign body has become embedded in the eye, do not remove it and do not attempt eye wash. The casualty should be referred straight to hospital.

Eyes should be covered to immobilise them and reduce further damage. As the eyes have a sympathetic movement system, meaning that they both move in synchronisation, it may be necessary to apply dressings to both eyes to fully prevent movement. If the foreign body is large, the dressing may need to be applied around the object.

Make sure you have the necessary first aid kits and equipment to provide effective first aid in your home or workplace.

Read our blog for more information on first aid, or contact us for further advice and information on our products.